Abstract:I have unquestioning confidence in China’s technological future. My confidence is based on what I have seen in product development in many SME’s in China over the past decade.

Confidence.

I have unquestioning confidence in China’s technological future. My confidence is based on what I have seen in product development in many SME’s in China over the past decade.

Back in 2005, very few Chinese engineers knew about FMEA [1] integrated quality assurance [2] or project management [3]. In 2009, I have taught these subjects, including the human aspects at Qingdao University. Today, almost all Chinese engineers are familiar with these subjects.

China is ready:

Today, Chinese engineers have reached a level of R&D capability that I estimate is higher than the American, but not yet at the German level.

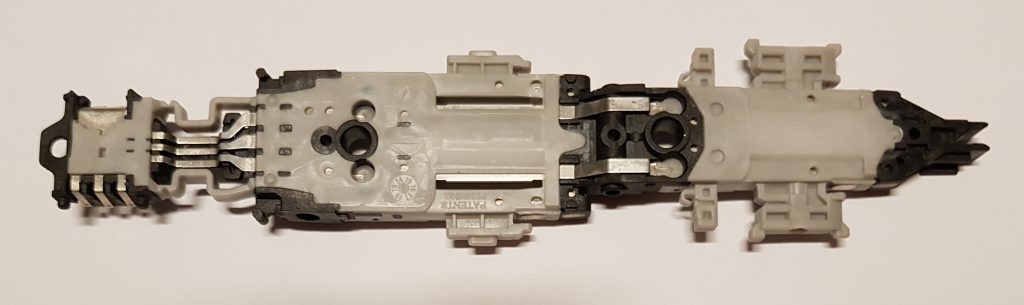

The product shown in figure 1 is a double solenoid [4]. The R&D was made in 2016 in Europe, knowing that it would be challenging to make it.

It is a four times smaller micro version of a previous product, with a lot of additional features integrated in the design. Making the product may be challenging but making the tools for such a product is even more challenging.

I have negotiated with specialised companies in Germany, Switzerland and Austria. They all hesitated, refused to make promises about meeting the requirements. Finally, I went to a dozen companies in Jiangsu, Shanghai and Zhejiang. Again, I could feel their hesitation. One wanted to take the challenge. They made prototype tools twice. And failed. I finally decided to work with a small company near to Suzhou without commitments, established a small team. We worked hard and closely together. After five months and at least six dozen trials and errors, eight sets of new tools, we finally made it. With the Chinese team, we made a brand-new extremely challenging product, something no-one else on this globe could make. We obviously patented the whole process.

Business culture:

As we all know: “Culture eats strategy for breakfast”. Business culture is extremely important. With a properly cooperating team, with the proper spirit, willing to take challenges it is possible to break through the wall of impossibilities and develop challenging new products.

Today, China is ready for that. At Huawei, they got it; they are fully aware of the importance of business culture.

Patent issues:

China will easily and in an entirely legal way overcome the issue that, in the chips business, many critical patents are owned by American multinationals. There are several ways to resolve this problem:

- Wherever possible, circumvent existing patents by a clever, brand-new design.

- Pay the (usually hefty) fee to the patent holder. Make it very clear to your customer(s) that a big part of the product cost is due to a patent fee.

- Buy the whole company, acquiring the corporate owner of the patent.

- Buy time: copy the patent in your own design, use it in prototype and pre-production to try-out your production, quality, logistics system. But don’t sell the pre-production products (that’s illegal)

- Use that time to develop another, better, proprietary design.

- Establish a team of patent-lawyers. They will legally analyse potential holes in the patent text. Use the holes to develop a product design, based on the gaps.

- Legally harass the patent holder. Challenge the validity of his patent(s).

- Keep track of all new patents in your industry. Buy patents when they’re still “cold”.

- Keep track of all companies in your industry that are in (financial or other) trouble. Buy or simply just take over their patents.

- Just bluntly use a patent of your competitor without informing him. Prepare for the consequences.

These are all quite common practices in the USA and Europe. I have used all of these techniques in the global automotive business. And I’m sure that at Huawei they also know these solutions.

So, yes, I am quite confident in China’s technological future. There is nothing that can obstruct China in its ambitions to surpass the US in not just chips, but any technology.

[1] Failure mode and effects analysis (FMEA) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet.

[2] Integrated Quality Assurance is anintegrated approach to quality, integrated quality assurance looks at the entire supply chain and addresses the issues of managing global supply chain networks. It involves a combination of process and product audits that covers both external and internal checks, focusing on supplier management, quality conformity of the product. It goes beyond “Just Testing”

[3] Project management is the process of leading the work of a team to achieve goals and meet success criteria at a specified time. The primary challenge of project management is to achieve all of the project goals within the given constraints, commonly: timing, scope, resources, quality.

[4] A solenoid is a type of electromagnet, the purpose of which is to generate a controlled magnetic field through a coil wound into a tightly packed helix. A solenoid, operating an electric switch is called a relay.